EEE’s remote working kits make practical activity possible

25 Nov 2020

Students in the Department of Electrical and Electronic Engineering (EEE) have been given the opportunity to carry out many of the practical elements of their programme from the comfort of their homes.

Equipped with a National Instruments myDAQ and individual bags of components for each unit, students are able to get hands-on with experiments regardless of whether they are on campus or studying remotely.

Dr Simon Watson, Senior lecturer in the Department explains more.

“Here at Manchester, one of the Department’s unique selling points has always been the amount of practical laboratory work students undertake, which can be up to 50 hours each semester for first year students. When the pandemic hit earlier this year, we knew we would need to explore how to continue offering this practical aspect and after discussions with all of the year one unit leads, the idea of the remote working kit was conceived.

Base kits have always been distributed to students within the Department. The difference this year is that we have also made available a special bag of components for each unit plus a fifth bag of general components, enabling our students to conduct all of the required experiments and practical work from their place of residence. Without these kits, the only remote option for these practical activities would have been via simulation based activity.

Each kit contains 100 discreet components in addition to the larger items. For those students who have been unable to collect the kits, we have committed to shipping these to them. To date we have distributed around 30,000 components to 292 first year students, over 40% of whom are remote. Furthermore, 250 second year students and around 50 students in year three who are studying a sub-set of units have also been sent out a kit containing a more advanced set of circuits. This has been a significant logistical challenge and has only been possible thanks to the hard work and dedication of a large number of academics, experimental officers, technicians, and administration support staff in both the Department and the School.

Students are using the kits for asynchronous lab activities where they work through tasks in their own time, and in synchronous lab sessions where demonstrators are available to support them if needed. Students are also using the kits for live tutorial sessions.

We are still running on-campus activities for students who are in Manchester and wish to come onto campus. As you can imagine, laboratory capacity has severely reduced; pre-COVID you could have up to three students working on a 1.8m bench. Now due to social distancing, we can now only allow one student per bench. This has resulted in us running the same lab session five times simultaneously across three or four different labs so we are essentially running up to 20 iterations to get the full cohort through. This has only been possible thanks to the fantastic support of our Graduate Teaching Assistants who have been willing to come on campus to help run the labs. These sessions have therefore been limited to strategic units or units where there are a small number of students. For example, some of our third year optional units and MSc units have between 50 and 60 students so it’s possible to get this number through in a couple of sessions. For the larger cohorts such as first year students with 292 students, it is logistically not feasible, so the remote working kits are fundamental in allowing these students to conduct some of that practical work at home. We can then get our students on campus in different capacities undertaking different activities through the computer cluster, still using their own kit.

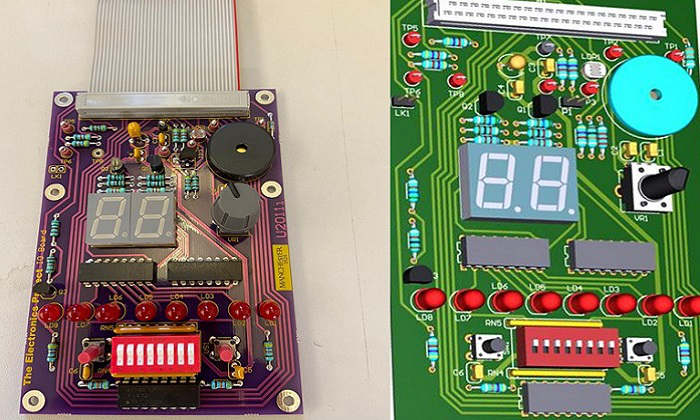

From week 8 onwards we will be running our core electrical testing activities. On campus students will learn how to systematically test a specially designed circuit board, which they will then use in semester 2 as part of a follow-on unit. Remote students will learn to use the same testing approach, but will make use of a variety of different simulations of the circuit board, including using 3D CAD models for visual inspections. Remote students will be posted the physical circuit so they can use it in semester 2. One of the main activities building upon this consists of students being given access to a broken circuit board which they must work through systematically to find the faults; which is an important practical skill to develop. Regardless of how students have chosen to undertake their studies, for activities such as this they are all able to do the same activity at the same time meaning we can run a single synchronous session with on-campus and remote students.

The costs of each kit is approximately £250 for first year students and £50 for second and third year students. The kit will remain with the students for the duration of their studies. There has always been budget built into the programme for providing the base kits but we had to secure additional funding to provide the additional components required to enable the students to undertake the level of practical work our University has become renowned for.

We are also rolling this out for the second semester so our second years will be sent a further package with more components to allow them to complete activities in other units.

I do believe blended learning is here to stay. It is something we have discussed for a while but I think we needed this impetus for us to make the transition. This year hasn’t been easy for anyone but I am looking forward to finding even more ways to diversify our offering whilst providing the level of teaching that will ensure that our students graduate from Manchester with a degree that is highly sought after by employers.”