Driving force

09 May 2018

How will our future cars be powered?

The race is on. The UK government has challenged the automotive industry to rethink how we power our vehicles. Expertise at Manchester could hold the key.

Fast-forward to 2040 – what will cars look like and how will they perform? Will we live in a world of self-driving and electric cars?

With the government’s announcement that it plans to ban the sale of petrol and diesel cars by 2040, manufacturers and industry are gearing up to meet the challenge.

At The University of Manchester, research and new knowledge is being applied to a range of technologies that could transform the efficiency of cars. This includes new lightweight materials and composite capabilities, better energy management for electric vehicles, smarter power distribution systems, emissions testing and analysis, and digital manufacturing techniques.

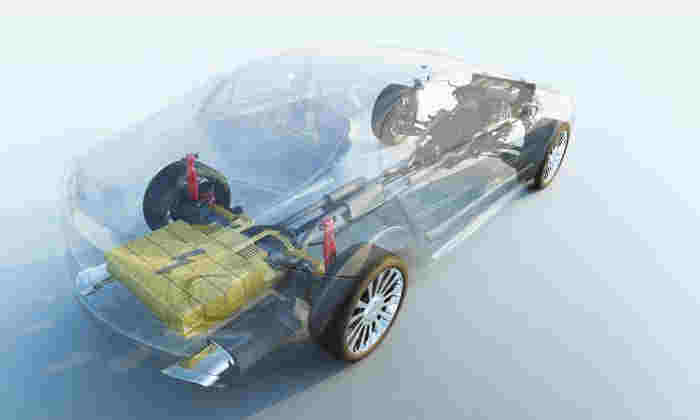

An increasingly critical area, however, is the power unit that will propel the electric vehicles of the future. This requires a transformation in current battery technology – and this is where Manchester is taking the lead.

Source of power

Demand is surging for alternatively fuelled – including electric and fuel cell powered – vehicles in the UK, with registrations increasing year on year by 23.9% in January 2018. Yet manufacturers have struggled to develop a battery that is both lightweight and delivers a reasonable driving range.

A solution could lie in the two-dimensional material graphene, which could make batteries lighter, more durable and suitable for high-capacity energy storage.

According to James Baker, CEO of Graphene@Manchester, the home of applied research in graphene, the application of new materials will be critical to driving the e-car revolution.

“Advanced materials will play a key role in delivering the many challenges of the next generation of automobiles – from reducing weight while maintaining safety to increasing range and performance,” he explains.

“We’re already seeing graphene-enhanced components delivering benefits, from helping to reduce weight of the car’s structure through to improving the performance of tyres.”

James shared his vision at a national forum hosted in Manchester and organised by the Advanced Propulsion Centre (APC), the body that aims to position the UK as a global leader for developing and producing low-carbon vehicles. The event gathered academics and business leaders from across the UK who are looking for breakthroughs in materials science to help transform the future of the country’s auto industry.

As a sign of its commitment, the government, working with the APC, is investing £500 million of funding to ‘research, develop and industrialise new low-carbon automotive technologies in the UK’, while industrial partners are expected to provide another £500 million of match funding to support collaborative research and development projects.

Going further

Many electric cars have a recharging range of around 100 miles or more, depending on make and model, which can be a real frustration to owners planning long-distance journeys.

A collaboration between Manchester’s National Graphene Institute (NGI) and Lancashire-based William Blythe Ltd has been set up to help address this. The project will focus on the development of anode materials – an important component of the battery – and aims to make the refuelling range of electric vehicles more competitive with their traditionally powered equivalents.

Andrew Hurst, Managing Director at William Blythe Ltd, says: “The combination of our capability in inorganic chemistry and the NGI’s global pre-eminence in graphene offers real potential to solve one of the significant problems limiting the adoption of electric vehicles.”

Meanwhile, the Henry Royce Institute – the national organisation based in Manchester that is leading on applied advanced materials research – is also helping to drive battery research by linking Manchester expertise with a wider research community and blue-chip business partners.

The Royce and its experts have played a key role in responding to the government’s Faraday Challenge, a £246 million, government-backed commitment over the next four years to develop batteries that can deliver electrification of the automotive sector.

“Our work will go some way in helping the UK to build its own Tesla-style Gigafactory to mass produce the quantities of batteries needed for UK-based carmakers,” says Dr Andrew Hosty, CEO of the Royce.

“As well as quantity, our research will also radically improve quality – and see us produce ever more efficient and safer batteries that will successfully power the cars of the future.”

Experts of the future

To continue to innovate, we need to keep developing our capability to look beyond traditional solutions – that’s the opinion of Richard Fields, a Research Associate at the NGI.

While acknowledging the government’s commitment to development through the Faraday Challenge, Richard says he would like to see more electrochemical engineers trained who specialise in energy storage.

“These are the people who will help bridge the gap between research and commercialisation,” he argues. “They can help design advanced instruments and fabrication processes that could enable a breakthrough akin to the technological advances in weaving looms during the 19th century.

“Energy storage and production technologies of the near future will raise profound ethical challenges.”

To address these challenges, an online module that looks at social justice and energy access issues is available to Manchester students, encouraging them to critically examine the use of energy in their everyday lives and consider the suitability of energy sources.

Sustainability is one of ethical grand challenges that the University poses to its undergraduates, equipping them with the knowledge and skills they need in order to create a fair and sustainable global community now and into the future.

The race is now on to respond to these challenges, as research and commercialisation in this area move into top gear.

Read more about our research into energy, advanced materials and industrial biotechnology at: